Have you ever been caught in the middle of a heated argument at the garage, with experts passionately advocating for their preferred grease? If you have, you know that choosing between lithium grease and silicone grease feels like selecting the ultimate warrior for a mechanical battle. I recall an intense debate among my fellow mechanics, each with a unique rationale backed by their experiences. That’s when it hit me: could this simple choice impact the machinery’s lifespan more than we assume?

In my engineering journey, I’ve delved deep into the world of grease types and how critical their roles are in lubrication processes. This article explores the nuances that make lithium and silicone greases distinct formidable options in the realm of grease comparison. By unraveling their key differences and applications, I aim to equip you with the knowledge to end such debates confidently and decisively. Let’s embark on this discovery together.

What are Lithium and Silicone Greases?

As a former Jeep engineer, understanding the intricacies of greases, especially in automotive applications, has always been a critical aspect of my career. Greases are more than just lubricants; they are the silent guardians of our machinery. Did you know there are over 20 different types of grease, each with unique properties? That’s right, and among these, lithium and silicone greases stand out for their distinctiveness.

In my years of tinkering under the hoods of Jeeps, I’ve learned why these particular greases are formulated the way they are. Lithium grease, for instance, is a staple in heavy-duty applications. Its mineral oil base thickened with lithium soap makes it remarkably stable at high temperatures, which is why it’s my go-to for joints, bearings, and chassis components that demand durability under stress. Not only does it perform exceptionally well in resisting water washout, but it’s also incredibly versatile, making it an essential part of any toolbox.

Silicone grease, on the other hand, is a different beast. It operates where rubber and plastic components need lubrication without degradation. Its silicone oil base and inorganic thickener make it ideal for applications where rubber gaskets and electrical connectors are involved. Over countless engine overhauls, I’ve seen silicone grease prove invaluable for dielectric applications.

Why Use Lithium or Silicone Grease?

Benefits of Lithium Grease

Can one grease truly outperform others in automotive applications? From my years of hands-on experience, I can confidently say that white lithium grease often does. I’ve seen firsthand how it’s consistently preferred by automotive enthusiasts, including myself, for its exceptional metal lubrication properties. Its ability to adhere to metal surfaces ensures that moving parts remain well-lubricated under various temperatures and pressures, which is crucial in the demanding environment of vehicle components.

What truly sets lithium grease apart is its versatility. Whether you’re working on chassis joints or door hinges, this grease provides a water-resistant barrier, defending against rust and corrosion. The grease for automotive applications must handle tough conditions and repeated stress; lithium grease excels here, withstanding extreme temperatures and pressure. This reliability is why it’s my go-to for ensuring longevity and smooth operation in diverse automotive systems.

Transitioning to silicone-based solutions, these offer different advantages, particularly around non-metal surfaces. Yet, when it comes to enduring and versatile metal lubrication, lithium grease holds a distinct edge, speaking to me as the essential choice for many automotive applications.

Benefits of Silicone Grease

Ever wondered why silicone grease is recommended for rubber and plastic components? Through my off-road projects, I’ve seen firsthand why it’s heralded as the best grease for plastic and rubber preservation. Silicone grease offers exceptional lubrication for rubber, maintaining the integrity of seals in various environmental conditions. Its unique adhesion characteristics ensure it stays in place, effectively minimizing friction without deteriorating the material.

The superior water resistance of silicone grease makes it indispensable, especially for applications where components face moisture or outdoor exposure. When working on challenging terrains, I realized the importance of using a reliable lubricant that wouldn’t degrade rubber or plastic gaskets over time. Choosing silicone grease becomes more evident when we consider its ability to prevent binding and sticking, consequentially extending the lifespan of rubber and plastic parts.

In continuation, understanding when to opt for silicone versus lithium grease comes down to the specific environmental demands and the material compatibility of your application.

How Do Lithium and Silicone Greases Compare?

Physical and Chemical Properties

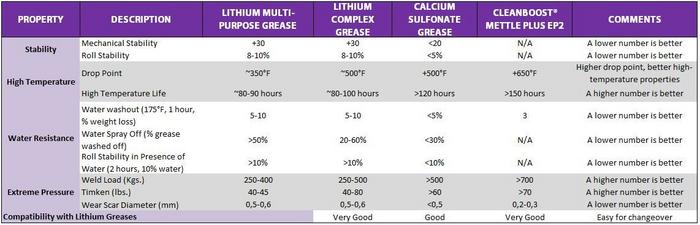

Analyzing the durability of grease is akin to uncovering how its core properties govern its effectiveness. Is it possible for the physical properties of grease to dictate its longevity and performance? My extensive examination of greases has led me to believe they do. The strength of adhesion characteristics plays a pivotal role. In lithium grease, this manifests as a robust ability to cling to metal surfaces, rendering it ideal for heavy-duty applications where enduring contact is paramount.

On the chemical front, water resistance distinguishes silicone grease. Its unique formulation ensures that it doesn’t wash away easily, making it a formidable choice in moisture-prone environments. These inherent differences in physical and chemical makeup reveal why each type is suited for select applications. Through my studies, understanding these properties has become key in making informed decisions between lithium and silicone greases. As we transition into application suitability, these insights will further underscore the optimal use cases for each grease type.

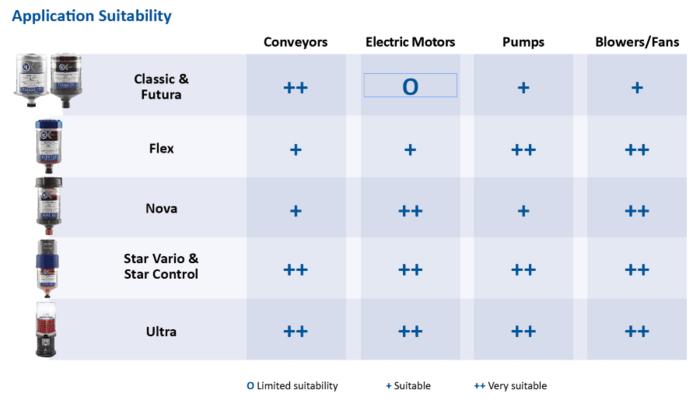

Application Suitability

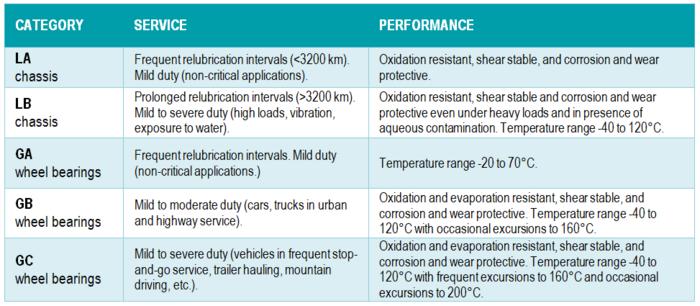

When it comes to practical use, how do we decide which grease fits which job? From my off-road adventures, I’ve learned that matching the right grease with the right application is essential to avoid costly repairs down the line. Knowing when to use lithium grease or silicone grease hinges on understanding the applications of grease. For instance, lithium grease is often the go-to choice for automotive needs due to its exceptional high-pressure performance and temperature resistance. This makes it suitable for components like wheel bearings and chassis parts, where robustness under stress is crucial.

Conversely, when dealing with plastics or rubber, such as in delicate electric components or car interior finishes, silicone grease shines bright as the best grease for plastic. It provides excellent lubrication and does not degrade or swell rubber and plastic materials, ensuring longevity and performance. Drawing from my hands-on experiences, it’s clear that aligning the correct grease with its ideal use case not only enhances functionality but also prolongs the life of your equipment. Armed with this knowledge, we can confidently tackle any challenge, from the rugged terrains of an off-road trail to the precise demands of vehicle maintenance.

When to Choose Lithium vs Silicone Grease

When faced with a lubrication choice, should practicality or performance take precedence? This question often haunts me, especially when I’m elbow-deep in grease, working on a beast of a machine out in the wild. As someone who has made critical choices in grease selection for tough off-road scenarios, I understand the importance of making an informed decision. The road—or sometimes, the lack thereof—demands both reliable endurance and optimal functionality from every component, making my choice of lubricant crucial.

In these moments, lithium grease often emerges as the practical choice, primarily for its incredible versatility. Its water resistance and excellent mechanical stability make it a reliable companion for bearing tasks or chassis lubrication, where durability is non-negotiable. I’ve often relied on lithium in places where sheer toughness needed an equally robust lubricant.

Yet, when performance takes the front seat, especially with rubber components or applications that require a non-reactive substance, silicone grease has often been my go-to. Its ability to withstand temperature extremes while remaining chemically inert is ideal for delicate operations involving plastic or non-metallic surfaces. This opens up a world of possibilities, from ensuring seal integrity to maintaining electrical connectors in optimal condition.

Ultimately, the choice between lithium and silicone grease is not merely a preference but a carefully considered decision based on the task at hand, a realization honed through years of hands-on experience.

FAQs

What is Lithium Grease?

What is Silicone Grease?

What are the key differences between Lithium Grease and Silicone Grease?

When should you use Lithium Grease?

When should you use Silicone Grease?

Conclusion

Have we truly uncovered the best grease for your application, or is there more to explore? Drawing from my extensive background, I can confidently summarize that the grease comparison between lithium and silicone offers crucial insights into their respective strengths and limitations. Lithium grease is celebrated for its robust lubrication and high-temperature tolerance, making it ideal for automotive and heavy-duty applications. In contrast, silicone grease excels in situations requiring water resistance and flexibility across extremes of temperature, perfect for weatherproofing and dielectric purposes.

The decision on which to use hinges on specific application suitability and the environment’s demands. While lithium grease is often the go-to choice for metal-on-metal contact, silicone grease provides excellent performance for rubber and plastic materials. By understanding these distinct attributes, both novice and seasoned mechanics can make informed choices, enhancing equipment longevity and performance. Yet, as always, the nuances of your unique situation may reveal even more possibilities.