Imagine revving up your Jeep for an off-road adventure, only to discover the metal beneath your vehicle’s once-gleaming exterior has succumbed to the harsh elements. This scenario isn’t a distant nightmare—it’s a reality for many, and the solution lies in choosing the right coating. Throughout my time as a Jeep engineer, I’ve witnessed the transformation that ceramic and powder coatings can bring to vehicle durability and performance.

But what sets these two powerhouse coatings apart? Understanding the differences and applications of ceramic coating and powder coating can not only save your vehicle from premature wear but also enhance its rugged charm. In the sections that follow, I’ll delve into the nuances of each coating type, sharing insights drawn from my experiences in the field.

Whether your goal is to bolster protection against the elements or achieve a specific aesthetic, knowing how these coatings stack up in durability and application might just transform your approach to vehicle maintenance.

What is Ceramic Coating?

Understanding the science behind ceramic coatings has allowed me to appreciate how they provide remarkable protection for off-road and adventure vehicles. Did you know that ceramic coating can create a protective layer that bonds at the molecular level with your vehicle’s paint? This fascinating process is one of the reasons why ceramic coatings have piqued my interest. They are made up of nanotechnology, combining silicon dioxide or titanium dioxide compounds to form a liquid polymer. This polymer is then applied meticulously to the surface of a vehicle, transforming into a semi-permanent layer that offers resilience against environmental contaminants.

In my experience, this sophisticated coating doesn’t just sit on the surface; it embraces the paint, enhancing the finish while safeguarding it from the harshest of elements. The magic lies in its ability to form a chemical bond that stands firm against dirt, grime, and even UV rays. Despite the ‘techy’ vibe, it’s this robust nature that really appeals to me, especially when considering the unpredictable terrains that I often find myself navigating. This appreciation for ceramic coatings has certainly elevated their position in my mind as an indispensable tool for any serious adventurer or vehicle enthusiast.

What is Powder Coating?

What if I told you that powder coating can withstand extreme conditions and harsh chemicals better than many traditional finishes? From my background in automotive engineering, I’ve seen firsthand how finishes need unmatched durability, especially when faced with the relentless demands of off-road vehicles. But what exactly is powder coating?

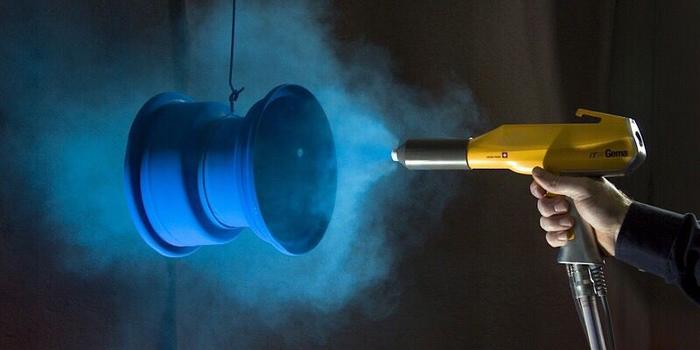

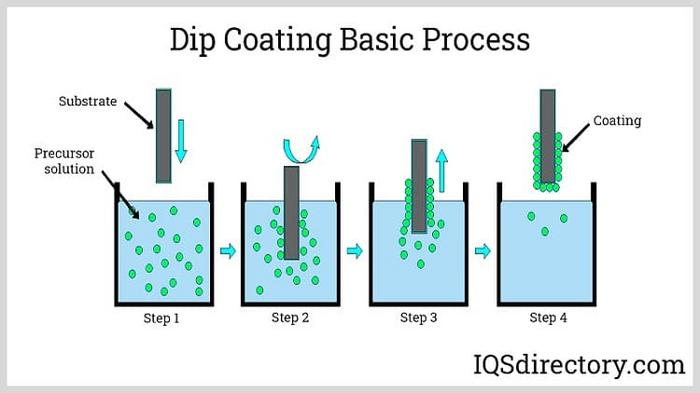

Powder coating is an advanced method of applying a protective and decorative finish to various surfaces, using a dry powder instead of a liquid paint. This powder is typically a blend of fine pigment and resin, which is electrostatically charged and sprayed onto the chosen surface. As the particles adhere, the object is heated, causing the powder to melt and form a smooth, solid layer that is incredibly robust.

In the world of off-road vehicles and demanding applications, this finish offers immense benefits. It’s not just about aesthetics; powder coating provides significant resilience against the elements and enhances a vehicle’s longevity. Through my experiences, I’ve come to appreciate how such coatings are invaluable in maintaining both function and form, standing up to many challenges that would break down typical finishes.

Why Choose Ceramic Coating?

In my years of working alongside fellow off-road enthusiasts, I’ve witnessed firsthand the incredible transformations achieved through ceramic coatings. Are the benefits of ceramic coating worth the investment for your vehicle’s maintenance? From my perspective, the answer is a resounding yes. Ceramic coatings offer not only protection but a lasting enhancement to your vehicle’s appearance, even when subjected to the rugged demands of off-road conditions.

The key advantage of ceramic coating is its ability to create a durable, hydrophobic layer on your vehicle’s exterior. This barrier effectively repels water, dirt, and grime, which means less time spent scrubbing mud from your last adventure and more time enjoying the ride. I’ve seen vehicles come out looking nearly as pristine as the day they were coated, even after enduring harsh elements. This isn’t just about a clean look; it’s about protecting your investment from corrosion and oxidation, preserving both function and value.

Moreover, the glossy finish of ceramic coatings enhances the aesthetic appeal of any vehicle. Imagine your rig shining in the sunlight, unburdened by dust or water spots, its colors vivid and surface smooth. This transformative sheen is something I find endlessly rewarding, a testament to the power of protection meeting beauty in the most demanding environments I’ve encountered.

Why Choose Powder Coating?

Is powder coating the ultimate solution for effective finishing in tough environments? With my experience in Jeep engineering, I can attest to the remarkable resilience of powder coating in facing both heat and the harsh elements typical of off-road adventures. This finishing technique provides a robust, long-lasting protective layer, essential for the rugged terrain that Jeep components often brave. From axle housings to skid plates, I’ve seen firsthand how powder coating offers an unparalleled defense, making sure these parts can withstand the journey.

Powder coating boasts several advantages that make it a go-to choice. The application process involves electrostatically applying a powdered polymer to a surface, followed by curing under heat. This results in a thick, even finish that’s harder and more resistant to chipping than traditional paints. For someone like me, dedicated to ensuring components survive rigorous conditions, such durability is non-negotiable. Furthermore, unlike liquid paints, powder coating doesn’t contain harmful volatile organic compounds, making it a more environmentally friendly option.

Whether you’re tackling the trails or simply seeking a reliable protective finish for metal parts prone to wear and tear, powder coating stands out as a formidable candidate. As we delve deeper into understanding these finishes, it’s crucial to appreciate how powder coating might just be the key to longevity in demanding settings, balancing toughness with sustainability.

How Do They Compare?

Durability

From my time evaluating off-road vehicles, I recognize that durability often dictates the choice of coatings and can make or break vehicle longevity. So, what truly defines the durability of a coating, and how do ceramic and powder options differ? This question has steered many of my comparative analyses, especially in the context of extreme environments where coatings are tested to their limits. Ceramic coatings boast impressive chemical resistance and are adept at protecting surfaces from corrosive elements, making them ideal for vehicles that face harsh weather conditions. They excel in heat resistance, crucial for parts exposed to high temperatures. On the other hand, powder coatings are renowned for their ability to provide thick, uniform protection against physical abrasions, ensuring a robust layer that can withstand physical wear and tear. Understanding these differences in durability helps determine which application best suits specific needs, especially in demanding scenarios like off-road environments.

Application Methods

Why does the method of application matter more than you think when it comes to coatings? When comparing ceramic coat and powder coat, the application techniques are crucial in determining the final performance and finish of the coating. Having spent years working with both, I can attest to how these methods can make or break your project. Ceramic coating often involves a more intricate, hands-on process requiring skilled precision and high-grade tools to ensure a uniform layer over complex surfaces. In contrast, powder coating involves electrostatically applying powder and curing it under heat to form a protective ‘skin’. These techniques aren’t just about technical skill—they influence the very durability and aesthetic of the final product.

Each has its advantages, but understanding these application methods and their inherent differences underscores the importance of professional coating services to achieve the best results. My experiences highlight that the choice in finishing techniques should align with your specific needs, given how significant the impacts can be on both durability and visual appeal. This comparison sets a foundation for evaluating other factors such as cost and environmental impact.

Cost and Environmental Impact

Are you spending more on coatings than you really need to, without considering long-term benefits and environmental impacts? As someone who’s spent years delving into automotive care, I’ve found that comparing the cost and environmental impact of coatings is crucial for informed decisions. Both ceramic and powder coatings share unique features, but their economic and ecological implications set them apart significantly. A close cost comparison reveals ceramic coatings often demand a heftier initial investment. Yet, their longevity and reduced need for frequent applications could ultimately balance out the expenses. Meanwhile, when evaluating the environmental impact of coatings, powder coatings typically boast a greener footprint due to their non-toxic, solvent-free formulation. Although ceramic coatings might enhance vehicle longevity, they’re generally associated with harsher chemical processes. Evaluating these aspects helps in identifying not only what fits your budget but also aligns with sustainable practice. Ultimately, understanding these factors equips you with the knowledge to choose wisely.

Which One is Right for You?

When it comes to selecting the best coating for your vehicle, what are the key questions you should ask? From years of hands-on experience working with off-road vehicle aficionados, I’ve learned that making the right choice can profoundly impact both performance and aesthetics. It’s paramount to first consider what you fundamentally need from a coating.

If your priority lies in withstanding the harshest off-road conditions, powder coating might be your best ally due to its durability and resistance to chipping. It offers a robust barrier that’s stood the test of time under myriad challenging environments. I’ve seen vehicles come back from grueling trails looking just as good as they set out, thanks to this reliable option.

On the flip side, if aesthetics and ease of maintenance hold more weight, you might lean towards ceramic coatings. They provide a slick, shiny finish that’s not only eye-catching but also incredibly easy to clean. This means less time and effort spent on upkeep, something I’ve personally come to appreciate when juggling multiple projects at once.

The decision doesn’t rest solely on these aspects. Cost and application process come into play as well. Understanding the nuances of each coating can indeed make all the difference, and I’m here to ensure you weigh these factors comprehensively before making an informed choice.

FAQs

What is Ceramic Coating?

What is Powder Coating?

How do Ceramic and Powder Coatings Differ?

What are the Applications of Ceramic Coating?

What are the Applications of Powder Coating?

Which Coating is More Durable?

Conclusion

In the battle of coatings, which contender truly reigns supreme? As I reflect on my experiences, it’s clear that both ceramic coating and powder coating have their merits, but understanding their unique strengths is essential for any vehicle owner. Ceramic coatings are unparalleled in their ability to provide a glossy finish and exceptional heat resistance, making them perfect for aesthetics and high-heat scenarios. On the other hand, powder coatings excel in offering durability and a broad range of color options at a generally lower cost, well-suited for those seeking robust protection and budget-conscious solutions.

My journey has taught me that choosing the right coating depends on what you value most—be it the sleek finish of a ceramic coat or the hardy resilience of a powder coat. My final thoughts are that by evaluating these critical aspects, you’ll ensure your vehicle not only looks spectacular but is fortified against the elements in a way that best serves your needs.