They said it couldn’t be done, but I proved them wrong. Armed with the right sandpaper grit, my humble garage became the birthplace of an impeccably revamped engine cover, proving that surface preparation is not just a prelude but the main act of a successful finish. The secret? Understanding how to choose the right sandpaper grit, a choice that can make or break the final outcome.

With years of experience in automotive engineering, I’ve learned that even the most extraordinary paint job will crumble without a solid foundation. Sanding is an art form often overlooked, yet pivotal. Join me as we delve into the intricacies of selecting the perfect sandpaper, revealing the techniques that separate an amateur’s blunder from a craftsman’s masterpiece. In this article, we’ll navigate through why, when, and how to sand your engine cover, ensuring you are well-prepared for your automotive journey.

What is Sanding?

What if the key to a flawless paint finish lies in understanding the nuances of sanding techniques? As I pondered this, I was transported back to my days as a Jeep engineer, where sanding transcended being merely a preparatory step—it became an art form, integral to ensuring both adhesion and durability of the paint.

From my experience, sanding techniques for engine parts are crucial for achieving that impeccable finish we all strive for. It’s not just about smoothing out imperfections; it’s about creating an ideal surface for the next layers of paint. Understanding the various sandpaper types is essential—each type serves a specific purpose, whether it’s removing old paint or creating a fine, smooth surface ready for priming.

In my journey with sandpaper, I’ve seen firsthand the dramatic transformation it can bring about. Selecting the right grit isn’t merely a technical choice; it’s a strategic decision that can determine the success of the entire project. In the following chapters, we will dive deeper into the specifics, ensuring your engine cover achieves the exceptional finish it deserves.

Why Sand the Engine Cover?

How many people truly realize that a perfectly sanded engine cover can extend the life of your paint job? Over the years, I’ve come to understand—and endlessly share—that surface preparation for paint is the foundation of any successful project. There’s so much more to it than merely grabbing the best sandpaper for painting and starting to work. It’s about investing in the success and longevity of your efforts.

In fact, as David Tracy aptly reminds us, the crucial role of surface preparation is what determines the outstanding adhesion qualities of paint, providing not just an aesthetically pleasing sheen but a durable and resilient finish. From my own hands-on exploits in the garage, I’ve witnessed how a careful, methodical approach to sanding transforms a basic engine cover into an artwork of precision.

The confidence you have in knowing that each coat of paint will adhere beautifully, withstanding the tests of time and use, comes down to the thoughtful consideration you give during this preparatory phase. My mission is to ensure that you, too, realize this often-overlooked truth—so that with each next project, you’re equipped with the wisdom and will to give your engine covers the treatment they truly deserve.

When to Sand the Engine Cover?

Have you ever considered that the timing of your sanding can be just as important as the grit of your sandpaper? This realization might surprise those new to automotive refinishing, but it’s a fundamental aspect I’ve learned through years of hands-on experience. Drawing from my engineering background, I’ve discovered that knowing when to sand is as crucial as mastering the technique itself.

During engine bay preparation, I found that timing plays a pivotal role in achieving a smooth, flawless finish. Sanding too early, when the primer hasn’t fully cured, can lead to uneven textures and require additional work. Conversely, sanding too late might mean contending with a hardened surface that’s tough to correct without risking damage to the base layer. My approach is to allow the primer to reach a firm, yet slightly pliable state—a sweet spot that ensures optimal adhesion without excess strain on the engine cover’s surface.

Understanding the sequence of sanding within the entire refinishing process is just as critical. Prioritizing this task during a phase where environmental factors, like humidity and temperature, are controlled can further enhance the quality of the finish. Timing, trust me, is not an arbitrary decision but a strategic one that can make or break the final outcome.

Who Should Sand the Engine Cover?

Is sanding engine parts something only professionals should attempt, or can the passionate DIYer master it as well? This question strikes at the heart of the automotive refinishing world, a place where technical skill meets creative endeavor. In my experience, there’s a certain satisfaction in working on your own engine cover, a blend of mechanics and artistry that few other tasks can rival.

Drawing from years in the garage, I’ve come to realize that both seasoned professionals and enthusiastic DIYers can produce remarkable finishes on engine covers. Each group has its advantages: professionals bring precision and efficiency, honed by countless hours of practice, while DIYers often inject a personal touch that stems from a genuine love for the craft. Armed with the right automotive refinishing supplies and a few key sanding tips for automotive parts, anyone can achieve a finish to be proud of.

The secret lies not just in technique, but in developing a hands-on connection with the material. As someone who thrives on that tactile journey, I encourage anyone, regardless of skill level, to embrace the process and discover their own potential.

How to Choose the Right Grit Sandpaper?

Different Grit Levels Explained

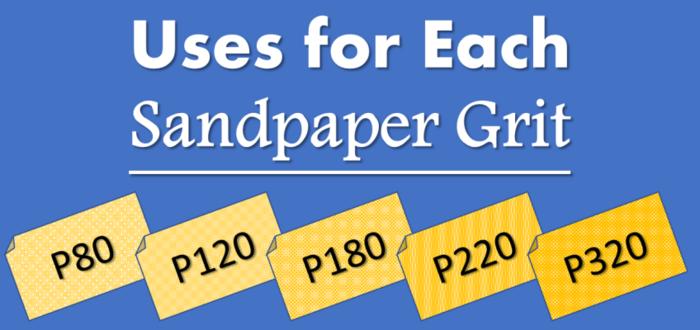

Did you know that selecting the wrong grit can lead to scratches that ruin your finish? Understanding different grit levels is crucial when preparing an engine cover. Through years in the workshop, I’ve learned that choosing the *right grit sandpaper* is key to achieving that perfect finish without unwanted marks. Grit levels determine the coarseness of the sandpaper: the lower the number, the rougher the paper, suited for removing paint or rust. In contrast, higher numbers provide a smoother touch, ideal for finishing touches.

When picking sandpaper for engine covers, it’s vital to match the *grit sandpaper* to the task. Coarse grits (40-60) are best for initial shaping, while medium grits (80-120) are great for cleaning up and smoothing out surfaces. Moving to fine grits (150-220) ensures a sleek finish. As David Tracy shares, understanding grit levels can help users avoid common mistakes, ensuring they choose the right paper for their specific engine cover needs. By mastering these nuances, you’ll ensure a flawless result every time.

Recommended Sandpaper Grits for Engine Covers

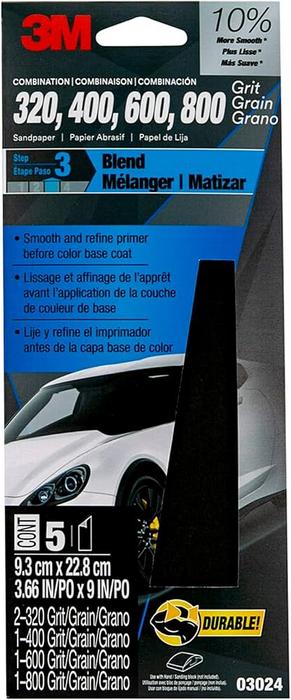

In selecting the best sandpaper for painting your engine cover, it’s crucial to understand how specific grits can profoundly impact your refinishing project. What are the specific grits that can make or break your engine cover refinishing project? Through my extensive experience, I’ve learned that starting with a coarse grit, such as 80-100, is essential for removing old paint and smoothing out any surface imperfections. As you progress, transitioning to a medium grit, typically around 220, will help refine the surface and ensure it’s primed for a smoother finish.

The final critical step involves using a fine grit, around 400-600, which provides the perfect balance for a silky finish before painting. Based on my experiences, using these recommended grits not only prepares the surface effectively but also enhances the paint’s adhesion and longevity. Integrating these grit recommendations within your sanding routine ensures a professional-quality finish, turning your engine cover into a standout component.

Sanding Techniques for Optimal Results

When it comes to preparing your engine cover for a finish that rivals a showroom display, technique is just as crucial as selecting the right grit sandpaper. What secret techniques can be employed to achieve a showroom-like finish on your engine cover? As someone widely fascinated by the art of refining surfaces, I’ve found that the most transformative practice is wet sanding. This technique involves using water as a lubricant, which helps to minimize friction, reduce clogging, and produce a smoother finish. Interestingly, wet sanding not only enhances the surface’s appearance but also improves workflow by reducing dust and debris.

When paired with careful grit selection—as emphasized earlier in our discussion on choosing the right sandpaper—wet sanding can significantly enhance the final outcome. Begin with coarser grits to level out imperfections and gradually move to finer grits to achieve that sleek, polished look. Consistency in pressure and motion is vital; too much force can mar the surface, while too little can be ineffective. Through deliberate, circular motions and regular rinsing to remove residues, the engine cover slowly transforms under precise care.

In my experience, adopting such sanding techniques for engine parts not only guarantees optimal results but also enriches the entire preparation process. This approach seamlessly connects to our exploration of grit selection, ensuring a holistic strategy that leads to excellence in detailing engine components.

FAQs

What grit of sandpaper should I use for preparing an engine cover?

Is wet sanding better than dry sanding for engine covers?

What type of sandpaper is recommended for metal engine covers?

How can I avoid scratching the engine cover while sanding?

Conclusion

Could the effort you put into prepping your engine cover be the difference between a mediocre job and a standout refinishing? Through my journey in refinishing engine covers, I’ve discovered that each stroke with the right sandpaper isn’t just a step in surface preparation, but a pivotal phase in achieving excellence. Selecting the appropriate grit ensures that the high-temperature paint adheres flawlessly, enhancing both the aesthetics and durability of your engine cover. This meticulous attention to detail signifies more than just compliance with technique—it embodies respect for the craftsmanship of the vehicle itself.

As I’ve concluded through each project, taking the time to properly sand and prepare with thoughtful grit selection transforms a basic mechanical task into an art. The value you infuse into this process is apparent in the final, stunning result. Embrace this opportunity to refine, and early preparation becomes your ally in elevating your vehicle’s overall appeal.