Can you imagine driving your pristine aluminum vehicle off the lot, only to discover an unsightly dent marring its sleek surface within weeks? As someone who has weathered the trials of automotive design, I know this scenario all too well. During my tenure as a Jeep engineer, dents were a frequent headache—proof of the vigorous off-road tests I orchestrated. Traditional repair methods often meant prolonged downtime and steep costs. But then came an innovation: paintless dent repair. This method transformed the landscape of automotive repair by offering an efficient and cost-effective solution without compromising a vehicle’s integrity. Particularly on aluminum vehicles, where conventional methods struggle, paintless techniques shine, allowing for quick, seamless damage fixes. This article unravels the journey of paintless dent repair for aluminum vehicles—exploring why it’s the go-to method among professionals and how it can revolutionize your vehicle maintenance experience.

Understanding Paintless Dent Repair (PDR)

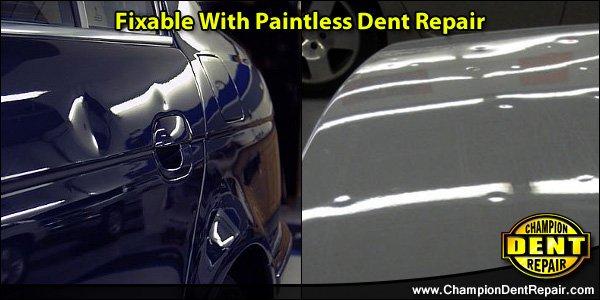

What makes paintless dent repair a favored choice among automotive professionals? This question brings to mind my own eye-opening experience with PDR, especially during my time working on rugged terrain vehicles like Jeeps. Observing the seamless restoration of aluminum surfaces captivated me; it was nothing short of artistry. Paintless Dent Repair (PDR) is an ingenious method that allows us to massage dents out of a vehicle’s body without disturbing its factory finish.

Fundamentally, PDR employs specialized tools and a keen understanding of the vehicle’s structural dynamics. The magic lies in the technician’s ability to gently push and pull the dented aluminum back into its original form, all while maintaining the integrity of the paint. It’s an intricate dance between skill, science, and a touch of artistry, which is why it’s often preferred over traditional methods.

Aluminum, being lighter and more flexible than steel, presents its own set of challenges and opportunities. Its properties make it ideal for PDR, as the softness of aluminum allows for more pliability during repair. Observing skilled technicians at work not only deepened my appreciation for PDR but also highlighted the value it preserves in vehicles, maintaining both aesthetic appeal and market value. Through this innovative technique, I’ve witnessed how auto repair can transcend from a functional necessity into an art form. This experience underscores why paintless dent repair remains a vital and favored approach in automotive repairs.

Why Choose Paintless Dent Repair for Aluminum Vehicles?

During my years of tackling the challenges of repairing dented aluminum components, I’ve seen firsthand how traditional methods often fall short. Could choosing PDR save you from costly repainting jobs? Absolutely. My journey with PDR started with a striking example: a client’s Jeep left pockmarked after a brutal hailstorm. Faced with the prospect of a respray and its inevitable pitfalls—mismatched paint shades and devaluation—I suggested paintless dent repair.

Paintless dent repair preserves the vehicle’s original paintwork, maintaining its aesthetic integrity. Aluminum, a notoriously tricky metal due to its unique properties, poses specific challenges that PDR addresses with finesse. This approach avoids the chemical-intensive processes of traditional repair methods, ensuring the original factory finish remains intact.

From an expert perspective, the benefits of PDR for aluminum vehicles extend beyond mere appearance. By preserving the original paint, PDR also safeguards the vehicle’s resale value. As I’ve practiced in the field, I’ve come to realize how choosing PDR can lead to substantial savings and enhanced longevity of automotive aesthetics. When I reflect on my experiences and my clients’ satisfaction, it’s clear that PDR is not only an effective solution but also a wise choice for those who treasure their aluminum vehicles.

Who Can Perform Paintless Dent Repair?

Is it better to trust a professional or attempt DIY dent removal? This question often stirs debates among car enthusiasts and everyday vehicle owners alike. From my personal experience, I can confidently say that not everyone can expertly perform paintless dent repair, especially on aluminum vehicles. The process requires not just skill, but also the correct tools and an understanding of the material, which is inherently more challenging than steel.

I vividly recall a time when a colleague, in his enthusiasm, attempted a DIY dent removal on a Jeep’s aluminum hood. Without the right tools and knowledge, the endeavor ended up requiring professional intervention later. This incident reinforced my belief that while DIY projects can be rewarding, trusting a professional is often the best option for optimal results, particularly for complex dents.

Having spent years learning the intricacies of paintless dent repair, I’ve come to understand that it’s an art as much as a science. Professionals bring with them not only expertise but also a keen eye for detail honed through experience. The right expertise can make all the difference in the outcome, ensuring the vehicle’s surface is restored to its original condition without compromising the paint or structure.

In conclusion, while the allure of DIY might tempt many, trusting an experienced professional is often the safest route to ensure a flawless finish in paintless dent repair for aluminum vehicles.

When is Paintless Dent Repair Effective?

When it comes to aluminum vehicles, understanding the effectiveness of paintless dent repair (PDR) is crucial. Can paintless dent repair be your first line of defense against hail damage? Absolutely. I remember a time when a severe hailstorm hit our area. My friend’s aluminum-bodied off-roader bore the brunt of it, with numerous shallow dents left scattered across its surface. In cases like this, PDR can be incredibly effective, particularly when the dents are minor and haven’t broken the paint.

One of the most significant factors that determine PDR’s effectiveness is how quickly you address the damage. Misalignment and dent resistance tend to increase if left untreated, making repairs more challenging. From my experience, tackling the repairs promptly can lead to better results. I vividly recall the satisfaction of seeing those unsightly dents vanish before our eyes, a testament to the skillful application of PDR techniques.

This rapid approach not only preserves the vehicle’s aesthetics but also its resale value, solidifying PDR as an essential tool in any car owner’s arsenal when facing minor damage. For aluminum vehicles, which are more prone to stretching and losing their shape, timely PDR is not just an option but often the best decision you can make.

How to Execute Paintless Dent Repair on Aluminum

Step-by-Step Guide

As a professional who has navigated the intricate world of Paintless Dent Repair (PDR) on aluminum, I’ve come to appreciate the art and science behind this meticulous craft. A fundamental question often arises for those venturing into DIY dent removal: What foundational steps do you need to nail down for DIY PDR?? Drawing from my experience, here’s how to efficiently execute PDR on aluminum vehicles.

Start by identifying the dent type and size as aluminum tends to be less forgiving due to its resilient nature. The key is to approach it carefully, ensuring you don’t worsen the damage. Next, assess the tools. I learned early on with my Jeep that using the right tools is crucial. Begin with a high-quality PDR kit specifically designed for aluminum. This ensures the pressure applied is even and minimizes the risk of cracking the paint.

Preparation is everything. Clean the surface thoroughly; any debris can affect your accuracy. Also, employing a steady hand and controlling the pressure are paramount. I always advise practicing on smaller dents first. This way, you develop a feel for the aluminum’s response without risking major damage.

This step-by-step approach not only highlights the technical process but also emphasizes the importance of patience and precision. As you refine your technique, every dent you encounter becomes a new lesson—transforming each challenge into a masterpiece of restoration.

Common Tools and Techniques

When diving into paintless dent repair on aluminum vehicles, the question naturally arises: What essential tools should every DIY enthusiast keep for effective dent removal?? My journey started during my engineering days, experimenting with various tools. I quickly learned the importance of having the right arsenal for automotive repair. While a basic set can suffice for minor tasks, I’ve discovered that specialized PDR tools are indispensable when you’re tackling aluminum. Their precision and flexibility make them truly stand out.

One of the most fundamental pieces of equipment is a quality dent removal rod set. These come in various shapes and sizes, providing the necessary leverage to carefully manipulate dents without damaging the aluminum surface. Additionally, having a glue pulling kit is incredibly helpful. With aluminum’s harder composition, the glue pulling method offers controlled pressure, essential for effective paintless dent removal.

Another often-overlooked tool is a good light source. In my early days, I underestimated the power of visibility during repairs, only to realize how pivotal it was in assessing dent shadows and depth. Therefore, a reliable PDR light is a must-have for any enthusiast wanting to refine their technique. Start with a basic set and expand as your skills develop. With each enhancement, you’ll gain confidence and precision, advancing your craft with every dent.

What to Expect from Paintless Dent Repair

As I delve into the realm of paintless dent repair for aluminum vehicles, I’m often asked, “Does paintless dent repair fit your budget without compromising quality?” This pertinent question sets the stage for understanding what to truly expect from the process. Paintless dent repair (PDR) is not just a buzzword; it’s an art form that combines skill and precision to restore aluminum paneling to its former glory without the need for repainting. From my experience, one critical aspect of PDR is its potential to save you both time and money, all while maintaining your vehicle’s original value.

I recall a time when a friend of mine, fresh from a minor fender-bender, underestimated the value of PDR. Initially, he viewed it as a cheaper alternative, skeptical of its effectiveness. However, he soon realized the measurable long-term benefits – there was no need for costly repainting, and his vehicle’s market value remained intact. As someone who’s navigated these waters, I can attest that PDR offers a quality solution without the depreciation headaches.

When considering PDR, expect a process that is efficient, typically completed within a few hours, and less intrusive than traditional methods. The real gem here is the preservation of the factory finish, which is exactly what you want when keeping both aesthetics and resale value in mind. Trust me, opting for paintless dent repair should be seen not as a compromise, but as a smart investment in your vehicle’s longevity.

FAQs

What is paintless dent repair?

Is PDR effective on aluminum vehicles?

What are the advantages of PDR for aluminum vehicles?

Are there any limitations to using PDR on aluminum?

How do I find a qualified PDR technician for my aluminum vehicle?

Conclusion

Is paintless dent repair the future of vehicle maintenance? After a thorough examination of the PDR process, I am convinced of its potential. From my journey as a Jeep engineer to a content creator, I’ve witnessed firsthand how embracing modern techniques like PDR is vital for those serious about maintaining aluminum vehicles. The PDR process offers a non-invasive, efficient, and cost-effective solution for dent removal, preserving the structural integrity and aesthetic of your car.

Choosing paintless dent repair not only enhances the longevity of aluminum vehicles but also empowers owners to make informed decisions. By reducing labor-intensive procedures and minimizing environmental impact through the elimination of paint and fillers, PDR stands as an innovative approach reshaping our traditional views on vehicle maintenance. Embracing these advancements can profoundly change how we maintain our cars, offering a sustainable and forward-thinking solution to vehicle upkeep challenges.