Imagine setting out on an exciting off-road adventure, only to have it derailed by a seemingly minor yet critical oversight—a compressor filled with moisture. This was the day I learned where true reliability in air compressor accessories lies. Experts often gloss over the fine details of air compressor air dryer filters, but today, I’m diving into those hidden truths that can make all the difference in performance. As a former Jeep engineer, I’ve seen how crucial air purification systems are to keeping the engines and systems I’ve worked on in peak condition. Their role isn’t just about avoiding moisture; it’s about prolonging the life of your equipment and ensuring every journey is smooth and uninterrupted. What are these filters, why are they indispensable, and when should you replace them to maintain system integrity? Let’s unravel these mysteries together, sharing insights from both technical expertise and personal experience.

What are Air Compressor Air Dryer Filters?

My journey into air compressor technology began with the daunting task of designing filtration systems for rugged terrains. It quickly became evident that the choice of air dryer filters wasn’t just a minor detail—it was pivotal. Did you know that not all air dryer filters are created equal? This realization was a game-changer in the way I approached system reliability and efficiency.

Air compressor air dryer filters are essential components designed to remove moisture, oil vapors, and contaminants from compressed air. They are critical in protecting both the machinery and the products being manufactured. In environments where precision is key, such as in electronics or pharmaceuticals, having the right type of filter can mean the difference between a smoothly running operation and an unexpected system failure.

I’ve learned through hands-on experience that selecting the appropriate filter isn’t just about compatibility; it’s about ensuring endurance and optimal performance. Prioritize quality, and your system will thank you with fewer breakdowns and extended service life. This concept was cemented during my early fieldwork when a neglected filter led to a shutdown that was both costly and preventable. That experience taught me that understanding each component’s role is essential in delivering efficient and reliable solutions.

Why Use Air Dryer Filters?

Why should we care about moisture in our air compressor systems? Early in my career, I found myself wrestling with persistent moisture-related issues in a tandem air compressor. It was a relentless challenge, causing productivity losses and repeated maintenance headaches. The breakthrough came when we installed a high-grade air dryer filter, transforming our operations with its moisture-removal capabilities. That experience taught me an invaluable lesson: moisture isn’t just an annoyance—it can critically undermine the integrity of the entire system.

Air dryer filters play a pivotal role in this. They act as the crucial barrier, protecting compressors from the detrimental effects of moisture. Moisture, if not adequately managed, can lead to corrosion, frozen pipes, and compromised end-product quality. These issues not only escalate maintenance costs but also jeopardize operational efficiency.

Through my firsthand experiences, I realized that investing in quality air dryer filters enhances system longevity, ensuring reliable performance. The insights I gained turned my attention to preventive measures, emphasizing the significance of well-maintained filters. Choosing the right air dryer filter isn’t simply about functionality—it’s about safeguarding your entire investment. It’s these lessons, withheld by industry experts until necessity struck, that I share openly to help you avoid similar pitfalls.

When to Replace Your Air Dryer Filter

When it comes to air compressor air dryer filters, knowing when to replace them is crucial, especially if you want to avoid the headaches I’ve experienced. I once faced a situation where a worn filter caused a system failure on a critical job. It was an expensive lesson, but it taught me the importance of vigilance. How can you tell if your air dryer filter is on its last legs? Recognizing the warning signs early is the key. I always recommend monitoring for unusual noises or a noticeable drop in pressure. These are telltale signs your filter is not functioning efficiently.

Having encountered the repercussions first-hand, I make it a point to perform regular check-ups, ensuring everything runs smoothly. It’s all about staying proactive. A little effort now can save you from costly failures down the road. Don’t let yourself be caught off guard—understanding these signals can make all the difference in maintaining your system’s integrity.

Where to Purchase Air Dryer Filters

When it comes to finding reliable sources for quality air dryer filters, my own experiences have taught me essential lessons. I once found myself in a bind, opting for an off-brand filter for a portable air drying solution due to its tempting price. It was a regrettable decision. The filter not only failed to perform but ended up causing damage to other components in my setup. From that mishap, I learned a crucial lesson: investing in quality is paramount when sourcing parts.

This brings us to a pivotal question: Is it worth spending extra on brand-name air dryer filters? My experience resoundingly confirms that it is. High-quality, brand-name filters are engineered to meet rigorous standards, ensuring reliability and longevity that lesser-known brands often lack. Investing in such filters means you’re investing in the steady performance and protection of your air compressor system.

When I search for these vital components, my go-to choices include reputable industrial suppliers and specialized online retailers. Websites dedicated to air compressor parts often provide extensive reviews and technical support, enhancing purchase confidence. Stocking trusted brands allows these outlets to offer products that reflect their own commitment to quality. As someone who values precision and dependability, aligning your purchases with these sources can make all the difference.

How to Install Air Compressor Air Dryer Filters

I remember a rather frustrating day trying to install a new air filter system in my garage. My mistake? Not double-checking the fittings. It meant running to the store multiple times. Now, I always advise checking compatibility before beginning installation—taking that extra step can save hours of headache.

Ever struggled with getting the right fittings during installation? It’s not uncommon, trust me. First things first: make sure you know the specifications of your filter. Identifying the correct size and type is crucial, not only to ensure smooth installation but also to avoid the same pitfalls I once faced.

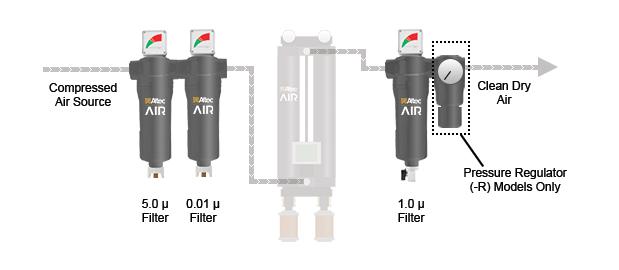

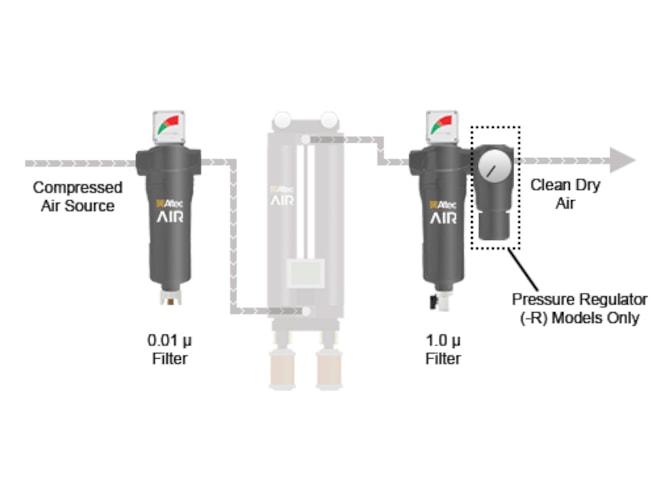

Start by gathering all necessary tools — a wrench, Teflon tape, and a screwdriver should suffice for most models. Next, switch off your air compressor and release all the air pressure. This prevents any mishaps and ensures a safer setup environment. Once it’s safe, locate the place where the filter will be installed, typically near the compressor’s outlet valve.

Now it’s time for the fittings. Use your wrench to securely attach the air dryer filter to the compressor’s outlet, ensuring there’s no leakage. Teflon tape can help ensure a tight seal. Connect and tighten all accompanying hoses, frequently double-checking their compatibility as you go. Recheck every connection point, mimicking the way I revisit every decision post-installation to ensure efficiency and durability.

Once everything’s aligned and secure, power up the compressor and test the system for any leaks. This approach has transformed how I tackle installations—turning what was once a tedious task into a smooth operation.

Setting Up Your Air Compressor System

During my engineering days setting up an air compressor system for an off-road facility, I encountered the complexities of plumbing that can make or break performance. What’s the most critical aspect of setting up an air compressor system? It’s proper plumbing and airtight connections. I learned the hard way that any leak, no matter how small, can cause significant performance failures down the line. Every time I double-check every connection to ensure they are not just tight, but leak-free, I remember those early mistakes and how they taught me the value of diligence.

Ensuring the plumbing is expertly configured starts with choosing the right materials. Heavy-duty hoses that can withstand pressure fluctuations and durable fittings resistant to wear are non-negotiables. In the past, I’ve seen projects suffer because someone tried to cut costs on these elements. Trust me, investing in quality components now could save you a fortune later on in repairs and downtime.

Once you have the right supplies, meticulously layout the system, mapping every connection before installation begins. This strategy isn’t just about preventing leaks; it’s about optimizing airflow for maximum efficiency. The goal is to create a streamlined path that minimizes pressure drop. Over the years, I’ve sharpened my abilities to anticipate where problems might arise, an expertise that’s invaluable, especially when dealing with fluctuating operational demands, like those in an off-road facility.

By focusing on these fundamentals, you align your air compressor system for seamless operation. Keep these insights in mind, and you’ll be well-equipped to avoid the issues I faced and maintain peak performance in your setup.

FAQs

What are the hidden benefits of using air compressor air dryer filters?

Why is it crucial to maintain air dryer filters in optimal condition?

How often should air compressor air dryer filters be replaced?

What are the consequences of neglecting air compressor air dryer filters?

Conclusion

Are you genuinely ready to enhance your air compressor system? Reflecting on all the projects I’ve tackled, the transformative power of moisture removal through air dryer filters cannot be denied. I’ve experienced firsthand how air quality impacts performance, and I’ve witnessed remarkable leaps forward simply by installing high-quality filtration systems. It’s a step often overlooked until issues arise, yet it crucially ensures every component of your setup runs smoothly and efficiently.

So, when should you prioritize these filters? It’s simple: always. Their importance in maintaining your air compressor’s health is underscored by the corrosive effects of moisture, something no serious operator can afford to ignore. My advice to anyone in this field is to never underestimate the value of clean air—it is the unseen hero of every successful operation. Whether you’re setting up or optimizing an existing system, investing in the right filter at the right time is a game-changer.